CUSTOM PRODUCTS AND OPTICS

CUSTOM PRODUCTS

In many cases the standard commercial optical components do not match the customer request/specification, resulting from internal development. We can support the customer with the design evaluation/validation, improvement/ optimization and subsequent prototyping and production.

We provide plastic lenses for different applications, glass optics, pressed blanks, IR, UV and visible windows, dichroics and flats in general. We can also provide diffusers and micro-optics for beam shaping as well as optics for LASER applications.

Based on the application’s features we can select the best optical solution to grant our customers the most effective cost-performance ratio.

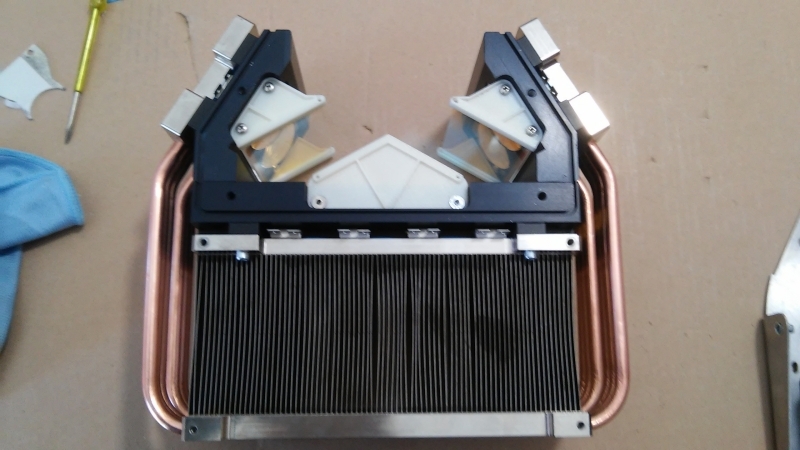

Besides spare optical components, we can supply complete optics solutions for any of the above-mentioned applications. We can also supply the necessary mechanics as well as the electronics if so requested. We provide integral optics solutions for imaging, optical systems support, including assistance with the athermalization process; more in general we provide optomechanics systems. We are available to analyze with you the application you need and find the solution that best fits your project.

PLASTIC OPTICS

We have a very long experience in plastic optic for different applications and environments. Plastic offers as many advantages as drawbacks. As for the advantages, we have the limited cost of the single components, the possibility to obtain complex forms such as the generic aspherical ones and microstructures, and the possibility of a better athermatization using the same material for the optical part and the mounting part.

ADVANTAGES OF PLASTIC OPTICS

Plastic is decidedly the type of material that allows for lower-cost production compared to glass, especially when it comes to high-volume manufacturing. Even if the initial investments could be high due to the cost of creating a moulds; it can be quickly recouped if the volume of pieces needed is compatible. We can offer different solutions/materials for the manufacturing of the moulds but, again, the best choice in terms of the cost-performance ratio we can suggest, will be based on the number of pieces our customers require and the quality required by their specific application

As for the disadvantages involved in the use of plastic, there is the limited number of types of plastic available for optical purposes (compared to glass), the limited thermal-range due to the risk of deformation, the high thermal-expansion coefficient and to the complexity of the moulding process which can easily result in uneven shapes, especially with thick components.

The quality of the mould surfaces finishing and moulding process both prove essential to obtain high-quality plastic optics, by defining the extent of shape precision and surface residual roughness that can be acquired.

GLASS OPTICS

Glass is the quintessential material that can be used in the optics field: provided that plastic can allow for a substantial reduction of costs, the optical quality and the thermal stability of glass, still prove unparalleled for the creation of ima-ging optics. However, hybrid solutions integrating polymers and glass, can offer a combination of the advantages of the different materials, playing down the involved shortcomings. Glass is also suitable for non-imaging applications when a high-temperature operation environment, mechanical stress, and weather conditions are at play.

Imaging glass optics are mainly realized by material removal, more specifically so when considering spherical profiles. However, the use of plastic deformation is also possible when considering aspherical profiles. Plastic deformation of glass can be obtained by softening the material and shaping it by pressing to obtain the mold-shaped profile needed. The tolerance values achieved in this instance are higher than those obtained through/in the polishing process. In any case, it is possible to create high precision generic shapes in glass to remove material in diamond turning: it is an especially costly solution best suited for scientific or military applications.